UNDERSTANDING YOUR TYRE AND HOW TO READ THE SIDEWALL MARKINGS.

Sidewall

This is the area of extra-thick rubber that runs from the bead to the tread and gives your tyre its lateral stability. It’s also where you’ll find all of the manufacturer information about your tyre, but what does a number such as 120/70 ZR17 M/C (58W) actually mean? Here’s a little guide to understanding these markings:

1) TYRE WIDTH

This number indicates the tyre’s section nominal width, measured in millimeters from sidewall to sidewall. In this case 120mm. Note: the actual physical width of the tyre on the rim can differ from the nominal width.

2) ASPECT RATIO

This number indicates the tyre’s aspect ratio or height expressed as a percentage of its width. In this case the aspect ratio is 70% of the 120mm width, making it 84mm.

3) WHEEL DIAMETER

On a sports bike tyre these letters are usually “ZR”. The “Z” indicates the speed rating of the tyre, which in this case means it is rated above 240kph/149mph. The “R” denotes that the tyre is of radial type construction. The “17″ denotes that the tyre is 17 inches in diameter whilst “M/C” means the tyre is for a motorcycle.

4) LOAD INDEX & SPEED RATING

The ‘58W’ indicates the load and speed indexes of the tyre and should always be looked at together when you buy a new tyre. In this case the ’58’ denotes that the tyre is rated for a maximum carrying weight of 236kg at maximum pressure. The “W” represents the maximum speed for the tyre when it is correctly inflated and being used under load, in this case 270km/h. Please remember however that when buying new tyres that you match the speed rating with the speed capabilities of your motorcycle, if exceeded, this risks tyre failure, hence you should always replace a tyre with one of at least the same speed rating so that you don’t reduce the speed capability of your bike.

Please refer to the load index and speed rating tables below for more information.

What are the different components which makeup your tyre?

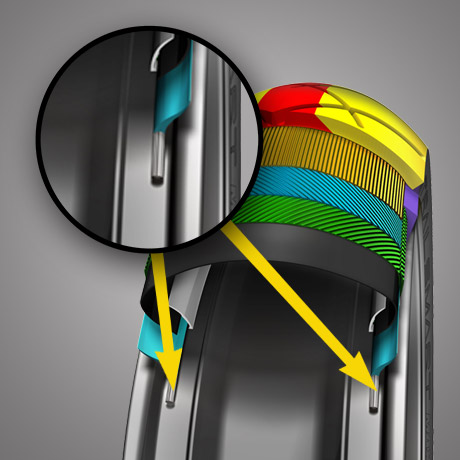

APEX

----------

The apex is used to reinforce the sidewall and sits on top of the bead. Apex shape and material play an important role in the way a tyre behaves and provides feedback.

BEADS

----------

The beads are made from high-strength braided steel coated in rubber, and create an airtight seal between your tyre and the rim of the wheel.

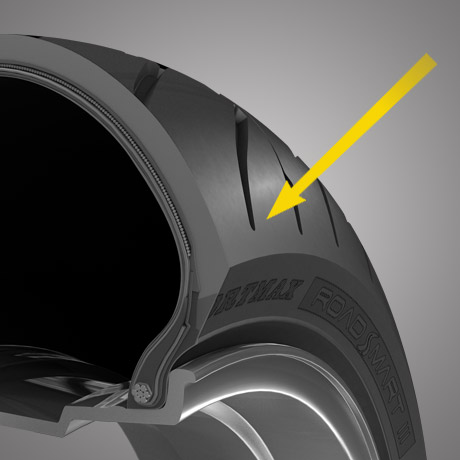

SHOULDER

----------

The shoulder area is between the centre area and the sidewall of the tyre. The shoulder design and construction plays an important role when the bike is leant over.

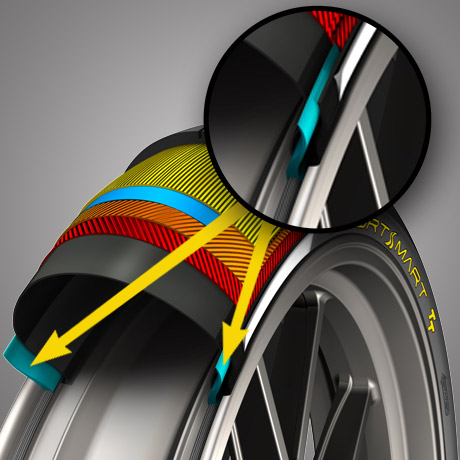

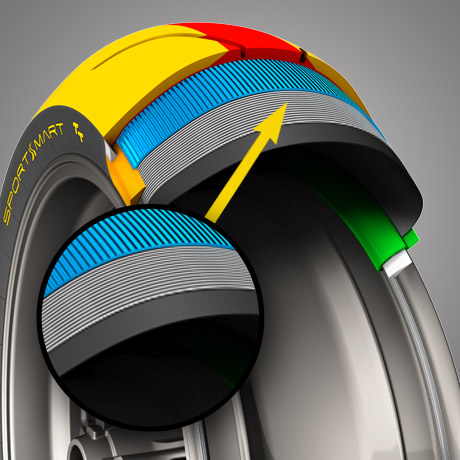

BELT

----------

Steel or aramid belts are placed around the tyre to reinforce strength, reduce dynamic growth at speed and provide rigidity. In some cases breakers, which are woven sheets of rubber-coated fabric, can be used for extra strength, puncture resistance and durability.

PLY

----------

The plies are the layers of fabric that make up your tyre’s skeleton, and are typically made of fibre cords that are woven together and coated with rubber. These allow your tyre to be flexible but not elastic. One or more layers called carcass plies placed directly above the inner liner give your tyre its strength.

TREAD

----------

This is the soft area of your tyre where the rubber meets the road. The tread provides both cushioning and grip, and its design and compound determine many of your tyre’s most important performance features. The tread can include different compounds for centre and shoulder area.

LOAD INDEX AND SPEED RATING TABLES.

LOAD INDEX

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

KG

82.5

85

87.5

90

92.5

95

97.5

100

103

106

109

112

115

118

121

125

128

132

136

140

145

150

155

160

165

170

175

180

185

190

195

200

LOAD INDEX

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

KG

206

212

218

224

230

236

243

250

257

265

272

280

290

300

307

315

325

335

345

355

365

375

387

400

412

425

437

450

462

475

487

speed rating

F

G

J

K

L

M

N

P

Q

R

S

T

U

H

V

W

ZR

KM/H

80

90

100

110

120

130

140

150

160

170

180

190

200

210

240

270

+ 240